Brief Introduction:

Model: UG-1615V1600*1500 working areaLarge CCD & protector for vision scan cutting200W oscillating knife & punch nifeCrane auto nesting software for leatherRuiDa RDD6584G controller

Application

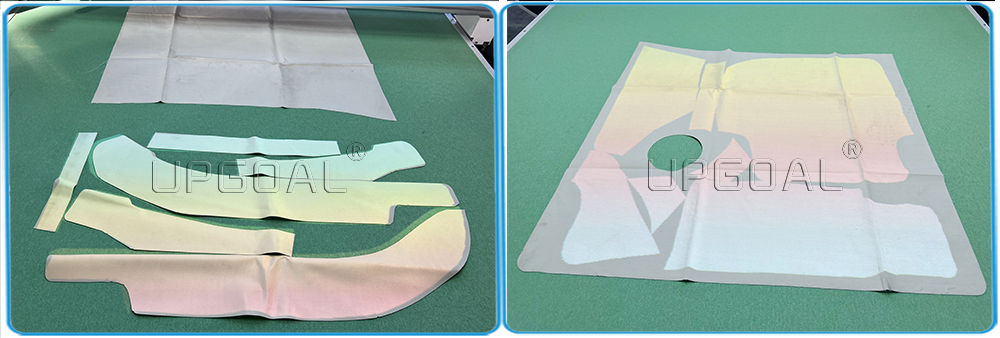

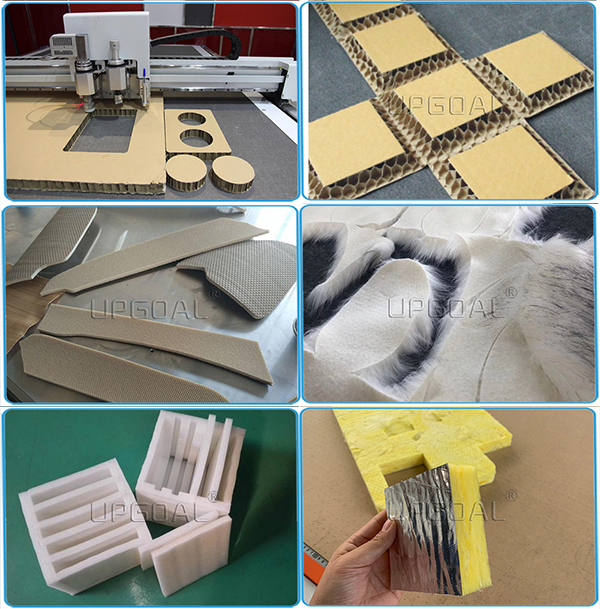

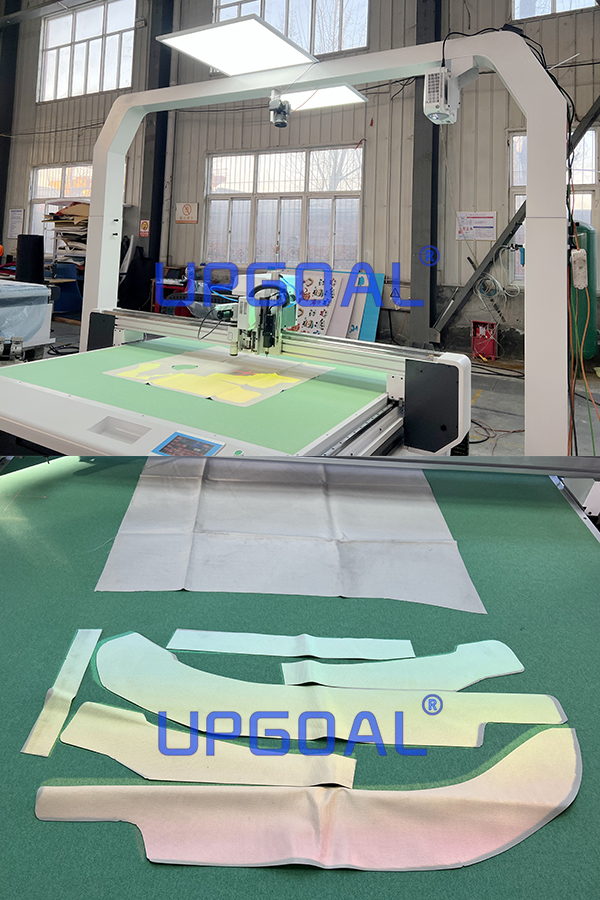

UPGOAL cnc oscillating knife cutting machine is widely used in cutting paper materials, automotive interior processing industry, used in the cutting processing of car seat covers, seat cushions, steering wheel grips, leather processing industry, leather cutting and punching, household fabrics, cutting of new technology materials and other industries.

Cutting materials

Leather, cloth, fabric, wool, fur, cardboard, corrugated paper, honeycomb paper, glass fiber, carbon fiber, self-adhesive, film, foam board, acrylic board, rubber, gasket material, clothing cloth, footwear material, luggage material, non-woven fabric, carpet, Sponge, KT board, PU, EVA, XPE, PVC, PP, PE, PTFE, ETFE and composite materials.

Features

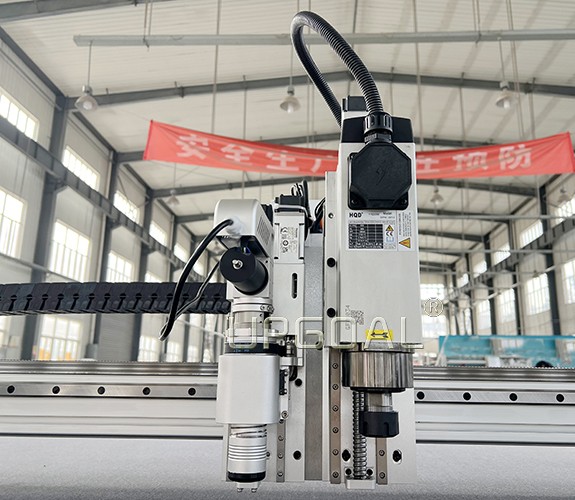

1. The ultra-high frequency 200W oscillating knife cutting(CLT brand) technology eliminates the irregularities of manual cutting, the limitation of the accuracy of the punching machine, and the scorching odor of the laser cutting machine. High efficiency and fast speed make leather and PU cutting become artistic enjoyment.

2. With adjusting punch knife(CLT brand), the cylinder drives the cutter head to move up and down, and can process materials: leather, cloth, soft glass, honeycomb board, KT board, corrugated board, gray cardboard, etc.

3. The industrial CCD camera system, equipped with professional focus lens, which can take a picture of each image. And the system can automatic change them as cutting paths, and then accurately cut the outline.It is professionally used for the rapid information collection of irregular materials or materials with printed patterns to achieve fast and accurate cutting.

4. Projector positioning system, instant preview nesting effects, convenient & fast.

5. Adopted famous RuiDa RDD6584G touch screen control system supports both USB and Ethernet connection, has a knife cutting controller with tool direction following control function. It integrates the processing of tools such as vibrating cutters, round cutters, milling cutters, and pressing wheels. It also integrates feeding, circular punching, and V-shaped special punching. Hole, pen processing, red light positioning and a series of functions.

6. With Crane leather auto nesting software, ealize automatic nesting function, multiple nesting methods, supported projection output, automatic contour and defect recognition, and automatically perform optical distortion transformation on leather photos without manual intervention. Make sure that the output profile is not deformed, consistent with real leather.

7.Whole cast aluminum vacuum table with imported thick felt, ensuring the machine stablity.

8. Equipped with 7.5kw high pressure air cooling turbofan, high adsorption ability.

9. Imported original PMI, Taiwan Linear square guide rail with ball bearing slide block which ensure high weight capacity, high precision, smooth and steady running. Adopt WMH brand,helical gears pinion and rack transmission for X and Y axis, higher running speed and efficiency, and more durable.

10. China DORNA 750W servo motor driver for XYZ-axis and 100W Panasonic Japan servo motor driver for DC-axis,, ensuring the processing speed & precision.

11. Buil-in control cabinet, save space.

12. Anti-collisiion device, ensuring the safe operation.

13. Semi-auto lubrication system more convenient for maintenance.

14.The cutting efficiency is high, the surface is smooth and flat, which greatly saves costs

15. A variety of tool heads(Vibrating knife, high-power round knife, punching knife, pneumatic knife, multi-layer knife, drag knife, half cutter, bevel cutter, milling cutter, etc. all can be installed), quick replacement to adapt to different materials

16.Convenient output, high-speed cutting, rapid prototyping, intelligent typesetting, saving materials

17.Supports multiple formats such as DXF, PLT, HPGl, etc., without cutting tools, saving manpower and material resources, and simplifying the work process.

18. Improve the cutting speed and efficiency, and provide strong support for high-speed cutting of the electric vibrating knife with a frequency of up to 25,000 times/min, up to 1000mm/s.

19 Smooth operation, fine and smooth incision, powerful function, can effectively solve various problems such as proofing.

Model | UG-1615V |

Effective cutting area | 1600*1500mm |

Working table | Fixed aluminum adsorption vacuum working table with adsorption felt |

Material fixed method | Vacuum suction system |

Knife | High power 200W oscillating knife(CLT) & punch knife(CLT) |

Scan & positioning | CCD camera( Canon) & Protector(BenQ) |

Control system | RuiDa RDD6584G(EC) touch screen control system |

Cutting software | RuiDa VcutWorks( supports WLAN cable & USB cable) |

Cutting speed | 0-1,500mm/s(according to different cutting materials) |

Cutting thickness | ≤40mm |

Cutting accuracy | ≤0.1mm |

Drive system | China NORNA 750W servo motor driver for XYZ-axis and 400W 100W Panasonic Japan servo motor driver for DC- axis |

Guide rail | PMI, Taiwan, linear square guide rail |

Transmission system | Helical rack and pinion transmission (WMH brand, Herion) |

Vacuum pump | Air cooling, 7.5KW |

Safety device | Anti-collision system |

Graphic format supported | PLT, DXF, AI, etc. |

Compatible | CORELDRAW, PHOTOSHOP, AUTOCAD, TAJIMA, etc. |

Voltage | AC220V ±10%,50/60Hz, single phase or AC380V ±10%,50/60Hz, three phases |

Machine size | 2180*1560*1560mm |

Net weight | 800kgs |